|

|

|||||

| Home | Tech | Features | Projects | News | Feedback |

|

||||||||||||

|

Ultimate

Traction, Built at home! By Bill Cooke |

| If you need the ultimate in traction then you need a locker! One of the best choices is the Detroit Locker. It's beefy, works non-stop and will give your truck the ultimate go anywhere ability you crave. One problem, that thing is hard to install, right? Wrong!!! If you have a Dodge with a 9 1/4" rear it's a snap! All you need is new bearings, some ring gear bolts and a dial indicator. If you don't own a 9 1/4 axle then as, it's hard to install. Have a shop or someone that truly knows what they're doing install it for you. Ford 9" guys, it's even easier for you to install, no c-clips! We didn't cover that install but the only difference is that you have to drop the center and the side adjuster are set with a spanner wrench. Very easy stuff. Now let's get to work and install a Detroit Locker! |

![]()

|

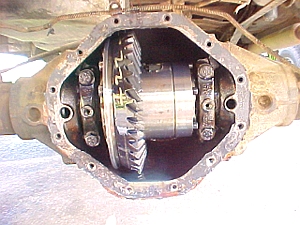

Here's the heart of the beast. If you've never taken the cover off your diff before then don't try this install. If the site of this somehow excites you more than it probably should then pick up the phone, order the locker and get to work. Tractech makes this soft locker for the C-clip 9 1/4 axle. It has the cut out for ABS so it can be used with late model axles as well. At just over $600 it's not cheap but then quality never is. You'll break a lot of other stuff before you ding a Detroit! Not included are the ring gear bolts, carrier bearings and diff cover gasket. Order those with the locker for a much easier installation. |

![]()

|

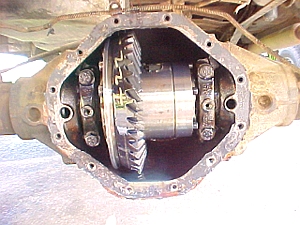

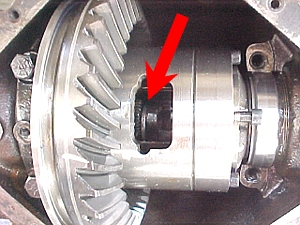

This is why the Dodge axle is so easy to work on. It uses threaded adjusters instead of shims. That means you just press the bearings on and slide in the locker. In order to get the old carrier out the adjusters will have to be backed out quite a bit. The carrier has a little lip that will get caught up and prevent it from coming out. If you are having trouble, back them out some more and see it that helps. You can get to them through this hole (arrow) using a drift. |

![]()

|

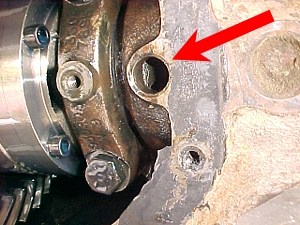

One neat little trick we found was with the bolts. After learning the hard way that they are left hand thread (backwards, and we snapped 3 bolts before we figured it out) we found out that they are also somewhat hard to find. Sure the dealer can get them for you at $6 a piece but we have a better idea. Seems they are exactly the same as GM 10 Bolt ring gear bolts. 7 Eleven sells those! Just make sure you get 12 of them, not 10. Now if you're wondering if you have to replace the bolts with the locker, don't make me come over there and slap you! Yes, you must replace the bolts. They have little grooves under the heads that keep them from backing out and those get worked when installed. After you remove them they are toast! Spend the 70¢ a piece and sleep better at night. I know I will. |

![]()

|

Here's a better shot of the adjuster. They

have a hex hole on the inside that is for torquing them down. That's fine

and all but where do you find the wrench? If you do let me know because we

never did. What we did instead we to use a 12" long, thin drift

through the access holes to set backlash and preload. It will work but is

slightly butch. The other alternative is to get a nut that fits the

adjuster and weld that to a pipe. Then fashion some way to get a torque

wrench on that and you're in business. Either way seems to work. Finding

the right wrench would be the way to go. After you're done with it you can

always rent it out to all your friends to help offset the cost.

The proper procedure is to place the carrier in the housing. Snug up the adjusters on both sides and set your backlash. Use a dial gauge unless your name starts with "Your Holiness" or something. There should be .006" to.008" play. That's pretty tight so your hand just isn't going to cut it here. With that set, tighten down the left adjuster just a little (10 ft. lbs.). Then move to the right adjuster and crank it down while rotating the carrier. This one goes to 75 ft. lbs. Once that is tight check the backlash again. It should be pretty close to what it was. The left bearing should have 75 ft. lbs. or force on it now too. Make sure everything is still running smoothly both forwards and back. This is the time to take care of problems. You should also check your gear pattern while you're at it. Ours was perfect, as it should be. We aren't changing anything but the carrier so the pinion should be OK. If it's not then you are in a world of hurt. That means new shims, a crush sleeve and pinion seal. Bad Magumbo! Like I said you should be OK but don't look at me if it works out otherwise, you knew this job was dangerous when you took it! |

![]()

|

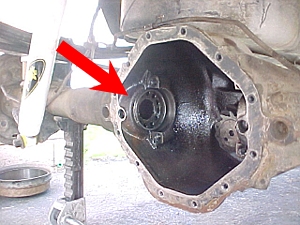

Now for the final step, getting the c-clips back in. You will have to remove the right hand bearing cap to get the bolt all the way out. Then remove the Allen head bolt that hold the center pin in place. The pin will slide right out. This gives you access to the c-clips. Slide in one axle shaft and place the clip on the button on the end of the axle (arrow). Pull that shaft out to hold the clip in place and do the same thing to the other shaft. Once that's done you can slide the center pin back in and tighten the retaining bolt down. Then reinstall the bearing cap, making sure it goes back on exactly as it came off and torque the bolts down to 75 ft. lbs. Then you can put the little adjuster locks in place. They simply bolt to the bearing caps and keep the adjusters from backing out. They have two little feet that need to sit in the threads of the adjusters to work properly. A little lock-tite hear would be a great idea. The last thing you want is a screw loose, in your axle that is. |

![]()

|

The only thing left to do is put the cover back on and fill it with gear oil. The other thing you will want to do is make sure the rear tires are EXACTLY the same tire pressure. The locker will know if they aren't. Driving the truck after the install was a bit interesting. We have a serious shift kit in the trans and it hits like a ton of bricks. That and the internal free-play the locker needs to operate correctly was barking the tires when the go pedal was heavily applied. 2nd gear chirps from this pig? I couldn't believe it myself. |

![]()

|

Contact Info: Tractech

Inc. |

Handling was exactly as it was expected. If you are uncomfortable with the sound of tires howling around corners then a locker might not be for you. It's also a little fun when going slow, uphill on a curvy mountain road. The locker will lock and unlock when you get on and off the gas so be ready for it. Rain, snow and ice also add a little more challenge but once you get to know how it will react it's fine. There were a few different reactions from a few drivers of the truck. Some loved it and other couldn't wait to get out of it, but that was on the street. Off-road there isn't a man, woman or child that wouldn't give there right arm for the abilities a locker provides. It really is that big a deal. Limited slips are fine if that's what you're into but there is no substitute for a full locker and there is only one Detroit Locker! Ask for it by name! |

![]()